CAM Data Exchange

The third edition of STEP-NC AP238 publishes improvements developed during 15 years of testing with new definitions for digital twin manufacturing, machine tool kinematics, integration with AP242, and machining process enhancements.

This edition combines additive and subtractive manufacturing with measurement so that turbine blades can be repaired more quickly and accurately, or teams of robots can cooperate during the assembly of complex structures such as air frame wings.

The improvements and testing makes AP238 ready for CAM to CAM data exchange. The Digital Manufacturing Implementation Forum is now working to enable this data exchange with support from STEP Tools. There will be four meetings in 2023, with the first focus on data exchange of toolpaths.

Manufacturing industry needs CAM to CAM data exchange so that experts can define solutions for new materials and tooling. The solutions can be developed by cutter vendors and other manufacturing specialists and sent to users for integration into their CAM systems.

Sending the data as AP238 enables the deployment in the CAM system. In the CAM system it can be verified in the context of other operations, included in work instruction generation, and posted using trusted and tested tools. The alternate of sending the solution as Gcode for cut and paste on the machine tool is very risky.

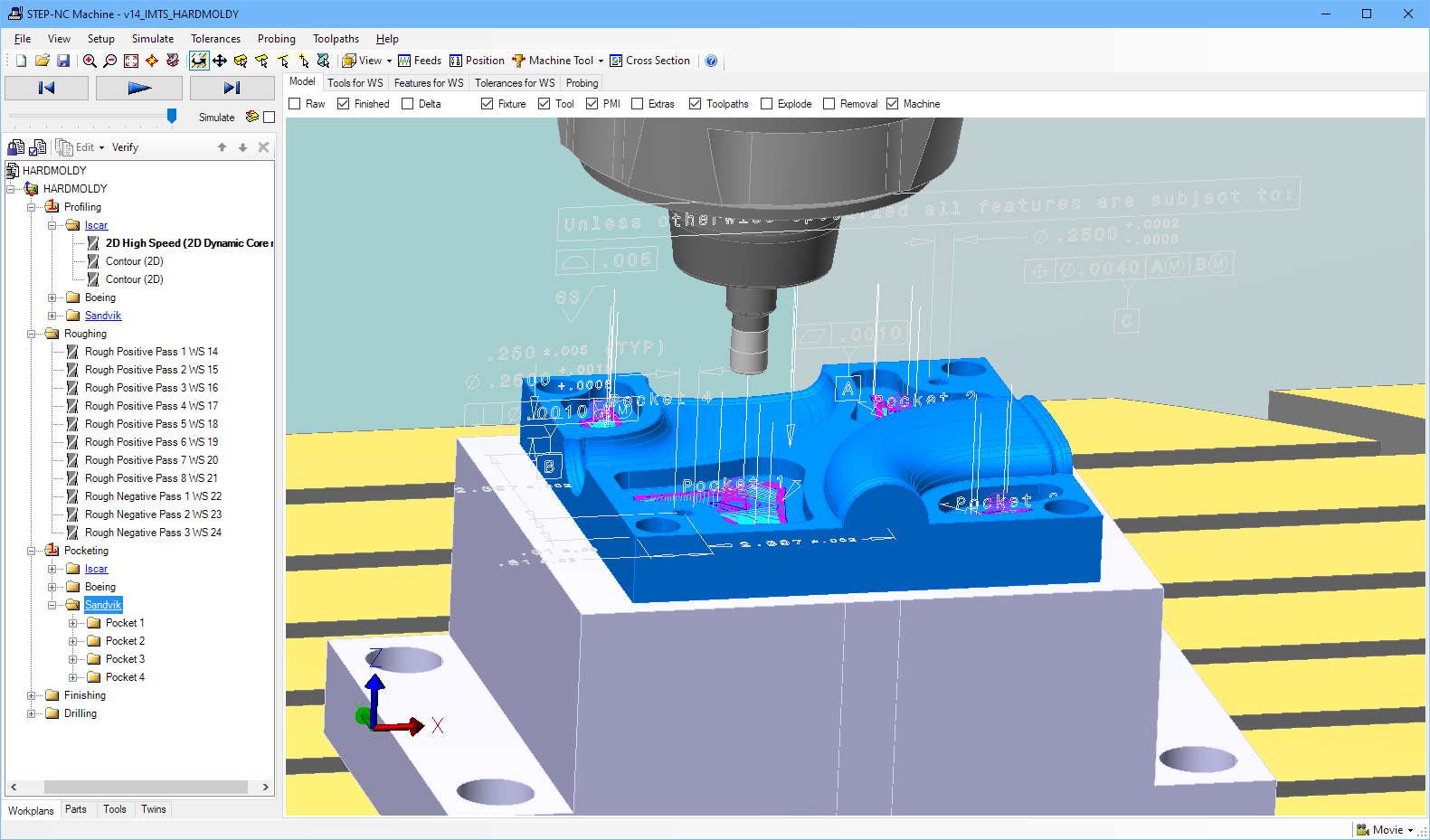

STEP Tools has developed multiple tools to enable CAM data exchange. The STEP-NC DLL is an API that can read, write and verify AP238 data. A manufacturing simulator has been developed that uses AP238 as its native data format. The simulator integrates AP242 tolerances so that results can be checked for different tooling. Each tolerance can be verified to ensure its requirements are being met.

To help you get started quickly, the stack contains source code for several sample projects. The Hello World project creates a very simple process which you can customize with with your own semantics or to integrate data from other sources, like CAD models for your tools, raw stock, or final workpiece. The Print Tool Moves and Print Workingsteps projects demonstrate how to iterate over an as-planned process, reacting to the tool changes, operation changes, and individual tool moves. The Generate example builds on these projects and shows how to drive different machine tools from an AP238 process.