STEP Tools Receives DARPA Phase II SBIR Award for "National Simulation Service" Project

Troy, New York - February 2, 2012 - STEP Tools, Inc. is pleased to announce a Phase II SBIR award from the Defense Advanced Research Projects Agency (DARPA) for a "National Simulation Service" that will be a next-generation web service for sharing, linking, editing, and verifying additive and subtractive manufacturing processes. It will use high-level product and process models to do these tasks more effectively and efficiently than is possible today. Users will provide CAM process and CAD product models for the stock, fixtures and cutting tools, and then the service will simulate the process to verify correctness and deliver in-process models of the product and process to other systems for inspection, correction and quality control.

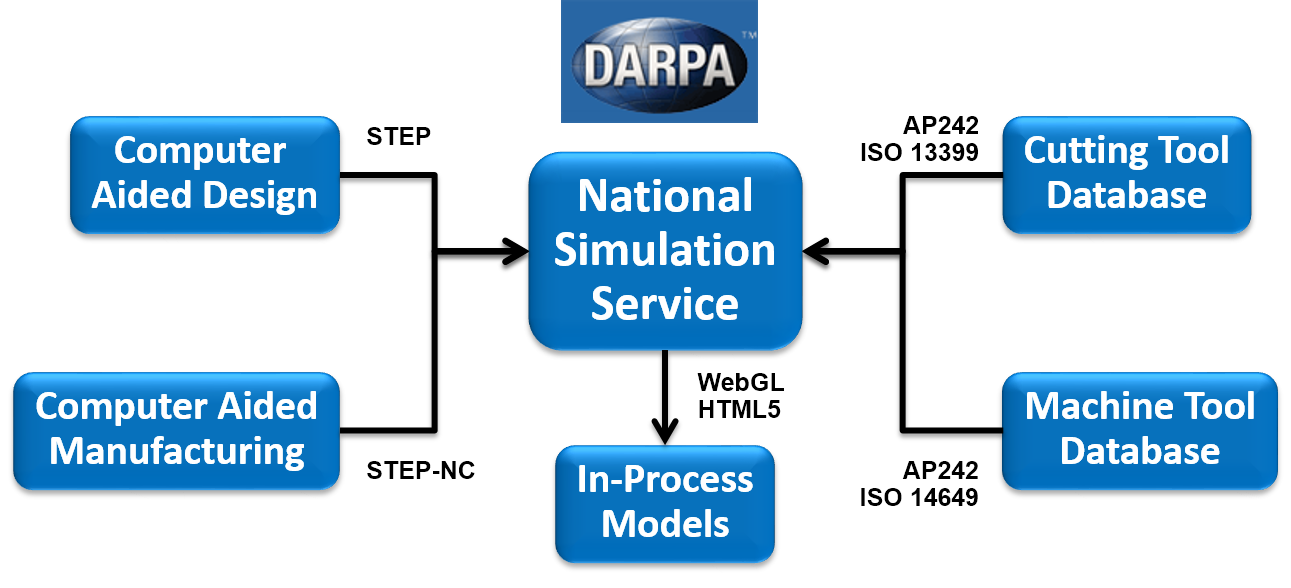

The figure above shows the service inputs. Users can upload “intelligent” data into the service using standard interfaces. CAD models with GD&T and PMI information are provided using a STEP interface. Process plans and tool paths are provided using a STEP-NC interface. Cutting tools are loaded using an ISO 13399 interface. Finally, machine tool models are loaded using an advanced AP242 interface that covers machine geometry, kinematics and accuracy tables.

The service will allow users to share data and reuse processes. When changes are needed, they will be able to replace models of the stock, cutting tools, fixtures and machine tools as necessary and rerun the simulation. If parts of the program are not working, then they will be able to correct them until they are working. The final result of the simulation will be evaluated against the tolerances defined by design and the users will be able to decide if the new process is ready for release to the shop floor for manufacturing.

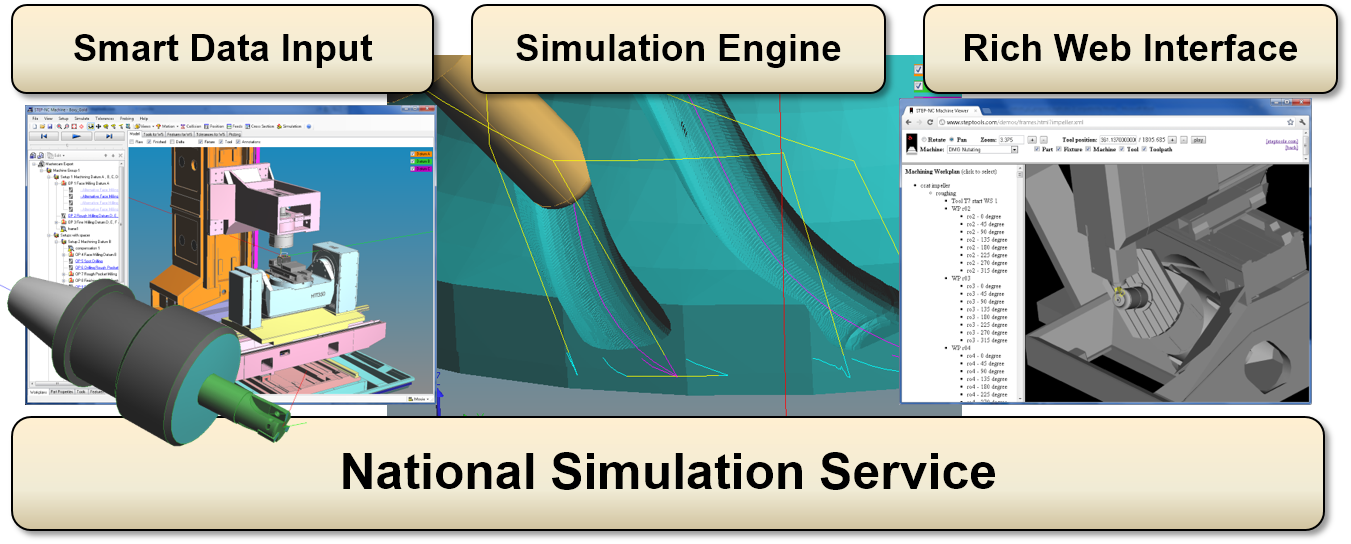

The Phase II work plan is divided into three task groups, as shown below. These three tasks focus on the following objectives with the overall goal to enable a science-based approach to manufacturing:

- Assemble “Smart data for smart machining” with standards-based interfaces for intelligent product models and rich process descriptions with enough information to do science based manufacturing simulation, predict tolerance results, and optimize by varying tools, machines, and processes.

- Provide fast, accurate response using a simulation engine that calculates resulting material volume and tolerance results, and can work with cutting and machine tool models to suggest optimizations like better feed rates and spindle speeds.

- Eliminate barriers to widespread adoption with a rich web interface that will be simple to deploy for large organizations, offer many benefits for distributed manufacturing teams, and open opportunities for use with mobile devices, tablets on the factory floor, and remote access from machine tools.

The National Simulation Service is part of a vision where many services are built for design, process planning and manufacturing. Within this framework the simulation service plays a critical role by independently validating the tolerances developed by the design service against the machine definitions supplied by manufacturing.