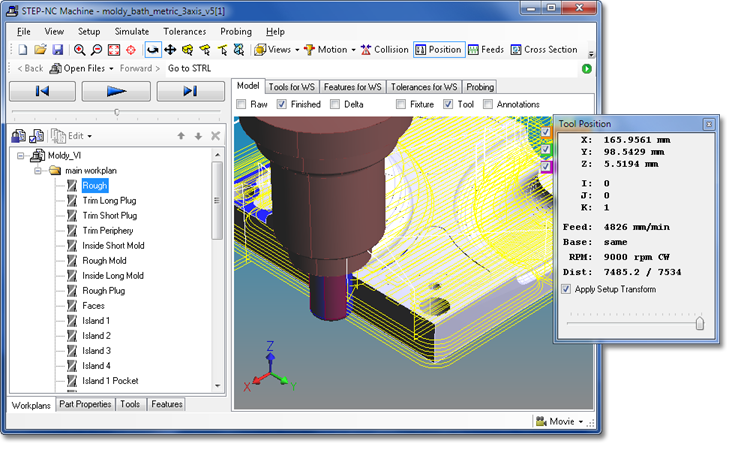

As you use STEP-NC Machine to display toolpaths and the tool

movements through them, you can see the coordinates, axis direction,

feedrate and spindle speed of the tool at any moment in time with the

Tool Position window.

As you use STEP-NC Machine to display toolpaths and the tool

movements through them, you can see the coordinates, axis direction,

feedrate and spindle speed of the tool at any moment in time with the

Tool Position window.

Bring up the Tool Position window by clicking the  Position tool button or selecting the

View | Tool Position menu entry. The window shows the tool

coordinates, axis direction, feedrate and spindle speed of the tool at

the current toolpath location.

Position tool button or selecting the

View | Tool Position menu entry. The window shows the tool

coordinates, axis direction, feedrate and spindle speed of the tool at

the current toolpath location.

The X/Y/Z fields show the tool position. The I/J/K fields show the tool axis direction. The Feed shows the feedrate at that point, taking into account any adjustment percentage given for that location in the toolpath, while Base gives the base feedrate for the entire toolpath. The RPM value gives the spindle speed. Finally, Dist gives the parametric position within the current toolpath.

If you want to change position, clicking the  Move Tool button enters toolpath picking

mode. Click on a toolpath and the tool should immediately move to the

new location. You can also move forward and backwards along the

current toolpath using the slider at the bottom of the Tool Position

window.

Move Tool button enters toolpath picking

mode. Click on a toolpath and the tool should immediately move to the

new location. You can also move forward and backwards along the

current toolpath using the slider at the bottom of the Tool Position

window.

If your program has workplans with setup placements on them, you can use the Apply Setup Transform checkbox to switch the position and tool axis values between their values in workpiece coordinates and their values in the transformed setup orientation. If your program does not have any setup placements, this checkbox has no effect.