Scientific, Authoritative and Reliable Digital Twin Manufacturing

The figure below shows a digital twin model of an airframe part. The model contains four thousand holes waiting to be filled by fasteners, and ten thousand holes waiting to be drilled. In this test the unfilled holes must be found and filled. The undrilled holes must be found, drilled and filled. All of the holes must meet requirements for position, placement and diameter. All of the fasteners must have sufficient grip to hold the pin, but not too much or the airframe will be too heavy. And all of the fills must have sufficient sealant to make the structure safe for traveling conditions.

Testing Boolean Removal

Inspired by the marching cubes algorithm used for surface fitting in computer graphics, we have been building tests that let us isolate the trickiest interactions and force our algorithms to deal with them under a variety of numeric conditions (exact, slightly overlapping, slightly separated, angled, etc.)

As an aside, Bill Lorensen did the initial work on marching cubes at GE just a few miles from our offices, and now some variation of it is in just about every 3D imaging system. Our hope is that in the not too distant future, just about every manufacturing system will build digital twins using the simulation algorithms we are perfecting here.

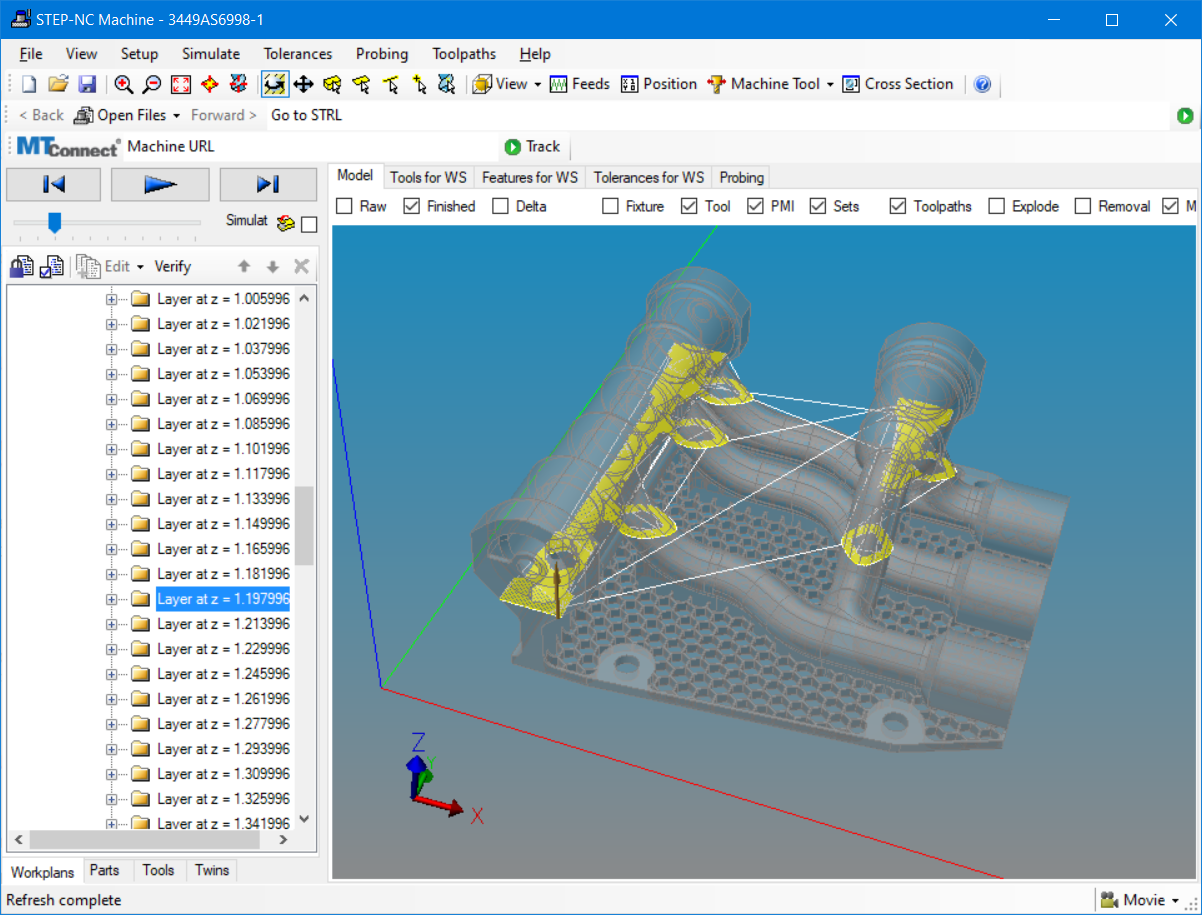

Powder Bed Fusion Generation

Announcing a Powder Bed Fusion Generation tool. The tool is being developed as part of a project to extend STEP-NC for powder bed fusion machines. In this initial configuration you can generate scan paths for STEP solids using the parameters described below. Please note the simple option if you just want to sample the output. The process control attributes can be set as text strings. In the next phase we will be updating the tool to set the process parameters to values appropriate to the dimensions and tolerances of the part as defined in the STEP model.

Read more and download tool

[Updated: 2024-5-30]

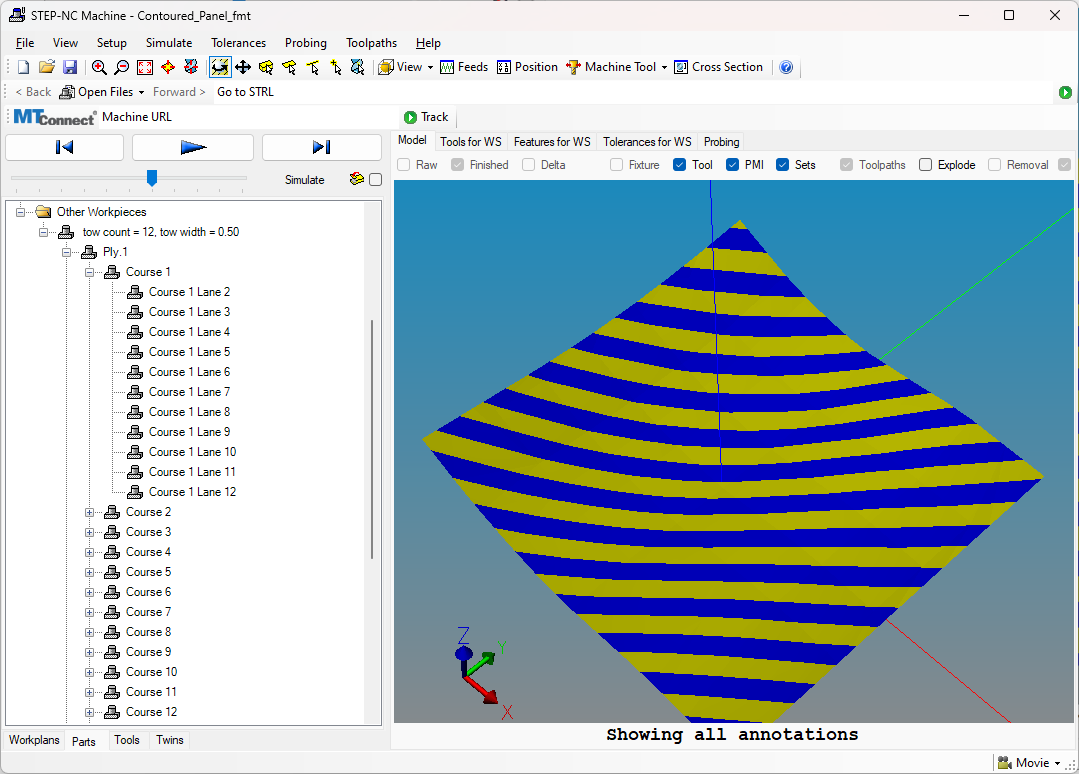

Tape Layup Generation

Announcing a Tape Layup Generation tool. The tool is being developed as part of a project to extend STEP-NC for tape layup machines. In this initial configuration you can split a STEP surface into tapes. Please note the simple option if you just want to sample the output. To make the input you need an advanced STEP translator that makes open shells trimmed by composite curves. The translator is available in some CAD systems as an option for those designing composite materials.

Open Accountability

Use ISO standards to control the quality of your products. No matter where your parts are being machined and assembled, they need to be monitored for quality. The right materials, the right assemblies, the right geometries and the right tolerances. You can do this in closed systems but there will be no transparency. Or you can do it using ISO standards that everyone can read and verify.

The STEP standards have been under development for 40 years. Over half of public CAD data is now in STEP. We have been working on extending STEP for manufacturing for more than 20 years. Yes, there are difficulties. You have to switch from manufacturing using codes to manufacturing using models, but even that is a benefit because you can see what you are making.

There has been too much delay! Multiple industries are in crisis because we are asking too much of our workers. You need Open Accountability to prove that something has been done, and show how it was done. The STEP standards developed by international experts are the open, digital twins on the digital thread are the easy accountability.

Saratoga TC184/SC4 Meeting a Success!

Thank you to all the delegates who made the 86th meeting of TC 184/SC4 a big success. STEP Tools enjoyed hosting you in the beauty of the Fall in upstate New York.

We started several new standards for manufacturing with digital twins and resolved multiple issues. The link above has the Star Trek and other meeting photos.

All Meeting Photos — Captains Chair Photos

Digital Twin Manufacturing

Announcing the STEP Python Interface, the faster way to program manufacturing solutions. The STEP Python interface reads CAD data, as defined by STEP, and makes digital twin as defined by ISO 23247. Everyone knows how much faster it is to make additive parts, but the same kind of acceleration can be realized for other kinds of manufacturing. Programming a third-party manufacturing system takes too much time and effort. A clever algorithm knows about the rules of your enterprise, and learns how to:

- Ensure all the engineering requirements are being checked and met

- Adjust to the non-availability of resources such as robots, cutters and fasteners

- Build measurable digital twins of your products in real time for enhanced quality control

The STEP Python interface is now available at no cost on

the Python Package Index

(PyPI) for simple install with pip on Windows, Linux,

or Mac machines.

Version 20 Software Released!

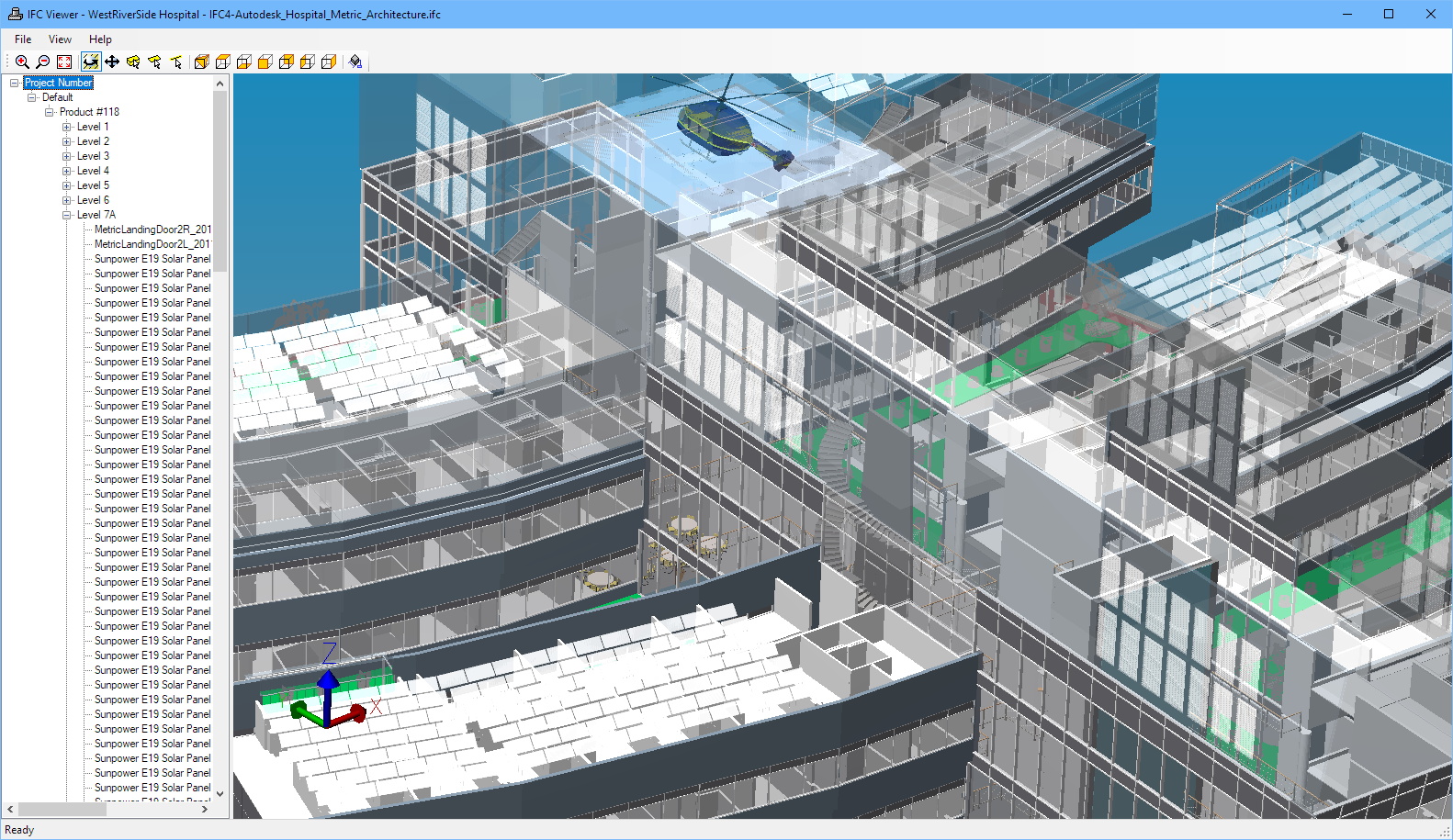

STEP Tools® Developer version 20 is now available, with support for the latest STEP AP242, STEP-NC AP238, and IFC 2x3 models. The IFC viewer is significantly expanded and our IFC mesher now supports CSG booleans and voids relations for window/door cutouts. Plus new Visual Studio 2022 support, Mach-O universal libraries for ARM and Intel on MacOS, and Linux compiler support for all distros currently in LTS back to RHEL7.

The STEP Tools® libraries power commercial CAD, analysis, and visualization systems and this latest release brings sematic tolerances, new geometry, STEP-NC manufacturing, and building information models to the fastest and most reliable libraries for making, using, and manipulating STEP, STEP-NC, IFC, and CIS/2.

The release notes for v20 have much more information about the libraries and new features! Our knowledge of these standards is unmatched across the industry. Whatever your goal, we provide the tools that you can rely on to reach it.

JSON From STEP-NC

We have been investigating JSON for describing manufacturing transactions and put together a small program to generate some using the STEP Python interface. We felt this was a nice example, so we are sharing it below.

The JSON output for the simple facing workingstep is shown below. It summarizes the position within the process, tool, operation, feature, and some other basic parameters.

Continue reading …

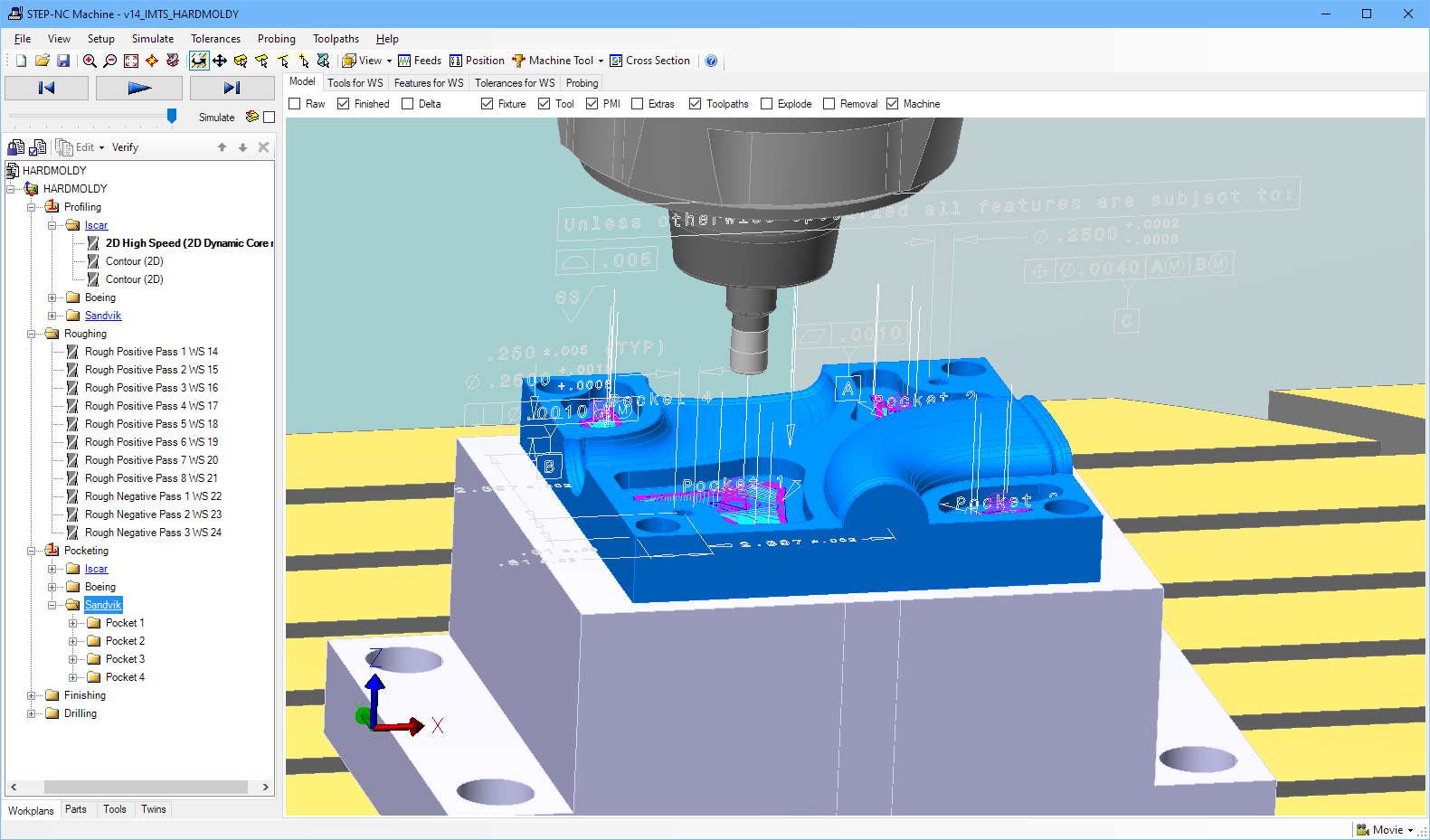

STEP-NC CAM Exchange

The third edition of STEP-NC AP238 publishes improvements developed during 15 years of testing with new definitions for digital twin manufacturing, machine tool kinematics, integration with AP242, and machining process enhancements.

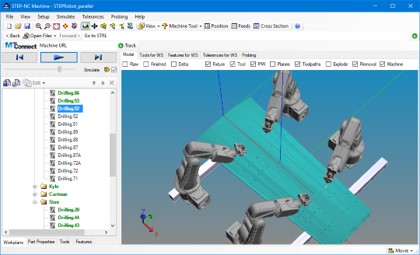

This edition combines additive and subtractive manufacturing with measurement so that turbine blades can be repaired more quickly and accurately, or teams of robots can cooperate during the assembly of complex structures such as air frame wings.

The improvements and testing makes AP238 ready for CAM to CAM data exchange. The Digital Manufacturing Implementation Forum is now working to enable this data exchange with support from STEP Tools® software. There will be four meetings in 2023, with the first focus on data exchange of toolpaths.

Manufacturing industry needs CAM to CAM data exchange so that experts can define solutions for new materials and tooling. The solutions can be developed by cutter vendors and other manufacturing specialists and sent to users for integration into their CAM systems.

Sending the data as AP238 enables the deployment in the CAM system. In the CAM system it can be verified in the context of other operations, included in work instruction generation, and posted using trusted and tested tools. The alternate of sending the solution as Gcode for cut and paste on the machine tool is very risky.

Continue reading …

One Million Unique Parts Machined

STEP is a standard for product model data and IFC is a standard for building model data. Both are very widely supported by CAD, CAM and BIM systems.

STEP-NC AP238 used to make 1,000,000 parts in 2019

- Argument won — STEP-NC is the machine control data for future aerospace.

- Boeing uses STEP-NC to machine parts for all its major airframes both single aisle and double aisle — even for satellites.

- Engineer who did the work promoted to Technical Fellow.

- Soon FAA is likely to want STEP-NC documentation for every machined part on an aircraft.

STEP AP242 Edition 2 is finished

- Every CAD system has an interface to read and write STEP.

- Edition 2 enables automatic measurement for on-machine CNC, and off-machine CMM.

- Edition 2 enables kinematics for digital twin manufacturing.

- STEP has the biggest and most widely tested information model for engineering.

IFC very popular for building models

STEP reduces the cost of manufacturing by allowing products, processes and machines to be assembled digitally for testing before delivery. IFC does the same for building construction.

- IFC technical meetings include thousands of attendees.

- IFC translators are being upgraded for latest STEP geometry.

- Building projects are producting very large multi-gigabyte IFC models.

- Every BIM system has an interface to read and write IFC.

If you own a CAD, CAM or BIM system, then we can help you extend and maintain your STEP and IFC interfaces with the latest libraries and visualization systems. Our librares are used by many of the leading CAD vendors, including NX and Autodesk, because they are the fastest and most reliable.

If your are a leader in manufacturing or construction, then we can help you use STEP and IFC to make better products. We are leading the deployment of 3D product models in manufacturing automation. There are many savings including a reduction in the cost of tooling of 15% or more.

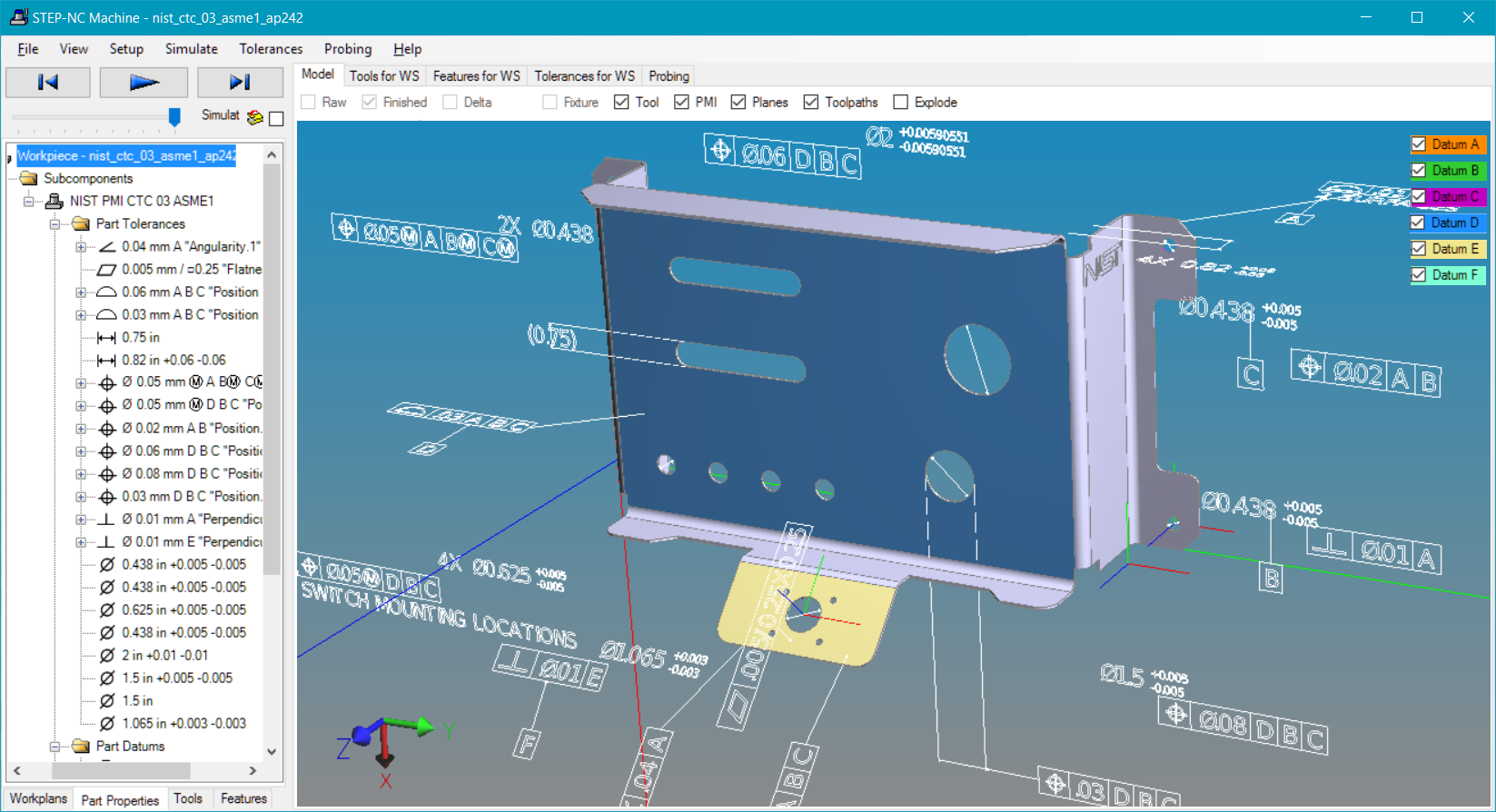

Enabling Closed-Loop Machining

August 29, 2019 — This short walkthrough shows a digital thread model in the STEP-NC Explorer. You will see geometry, tolerances, and process, simulate material removal, and discover how to get feed/speed, position, and calculated tool engagement cross-section information at any point in the machining process.

This information can close the loop with model-based machining and enable new applications for tool life and tool wear prediction, calculation of forces and heat, and many other possibilities.

Build it Here, Build it Now, Build it Right with the Digital Thread

On July 12, 2017, a team led by STEP Tools, Inc. stretched the digital thread farther than ever before - from design, through manufacture, and into five axis measurement.

The Digital Thread is a vision for manufacturing that opens many new opportunities. You can build it here because the thread is interoperable. You can build it now because the models in the thread enables full safety checking. Watch the video to see how to build it right.

On machine measurement will replace less responsive approaches because the integrated tolerances, machine feedback and linked evaluation give results before a part leaves the machine.

We challenge the machining industry to start delivering these benefits. At IMTS and JIMTOF 2018 we will supply test parts and confidential evaluation of the measurement results. We want you to demonstrate that you too can build it here, build it now and build it right.

Continue reading …

Solutions and Expertise

STEP-based solutions for CAD or engineering analysis, bill-of-materials, or supply chain integration: CAD shape, tolerances, assemblies, import or export, desktop or web visualization.

STEP Concepts

STEP Data

IFC-based solutions for BIM systems: translation, bill-of-materials applications, and visualization.

Connect product design, manufacturing, and inspection with a digital twin, built in real-time while machining with our new 3D model-based simulator. View from any mobile device, automate metrology, collaborate with supply chain, and real-time optimization.

Other Services

We offer training and support. We also have standards development experience and host forums, and an EXPRESS schema archive.