CAM Data Exchange with STEP-NC on the Digital Thread Demonstrated at IMTS 2014

Boeing, Okuma, ISCAR, Sandvik Coromant, and STEP Tools worked together to show CAM Data Exchange with STEP-NC on the Digital Thread. The result was a 15-30% improvement in machining time resulting from the collaboration enabled by a digital thread using STEP-NC.

Boeing created a baseline machining process for a mold part, then sent it to Sandvik and ISCAR for optimization. All machining was done in titanium, a range of CAM software was used, and all communication used STEP-NC. The result was a single digital thread for the part, with one STEP-NC description containing all three process options, plus CAD models for the part, rawpiece, and tooling.

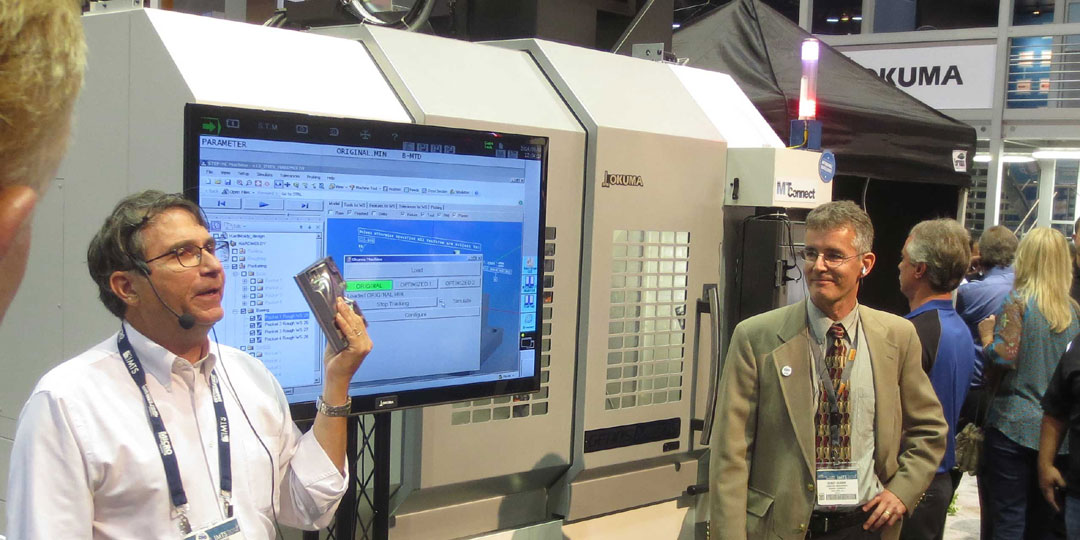

In the Okuma booth at IMTS, titanium parts were cut each day from the STEP-NC description. STEP Tools provided the STEP-NC interface for the Okuma control. It showed the live machine tool state in context with the STEP-NC program with live updates extracted via either MTConnect or the native THINC API. STEP Tools also demonstrated a material removal simulator that can build a 3D model in real time for the as-cut part. (See the Multikeo Digital Twin for a more recent demonstration)

The user interface for loading STEP-NC data into the CNC was a one-click process, with several configurable presets for machining parts at different places on the table. STEP Tools also supported the CAM exchanges with its experience and technology stack.

Ultimately, machining from models resulted in a measured 15-30% improvement in machining time because the digital thread using STEP-NC made it much easier for Boeing to collaborate and access the tooling and process expertise within ISCAR, Sandvik, and other sources.

Jim Kosmala of Okuma and David Odendahl of Boeing described the business cases for model-based machining at the TRAM2014 Aerospace Conference, which was running concurrently:

David Odendahl of Boeing showing the Okuma control on a larger display screen with the STEP-NC process description.

David Odendahl of Boeing showing the Okuma control on a larger display screen with the STEP-NC process description.

Three titanium mold parts on a fixture, each machined with a different process.

Three titanium mold parts on a fixture, each machined with a different process.

A finished mold part. The operator is switching to one of the three alternate processes in the STEP-NC for the next machining cycle.

A finished mold part. The operator is switching to one of the three alternate processes in the STEP-NC for the next machining cycle.

Legal notices and trademarks.